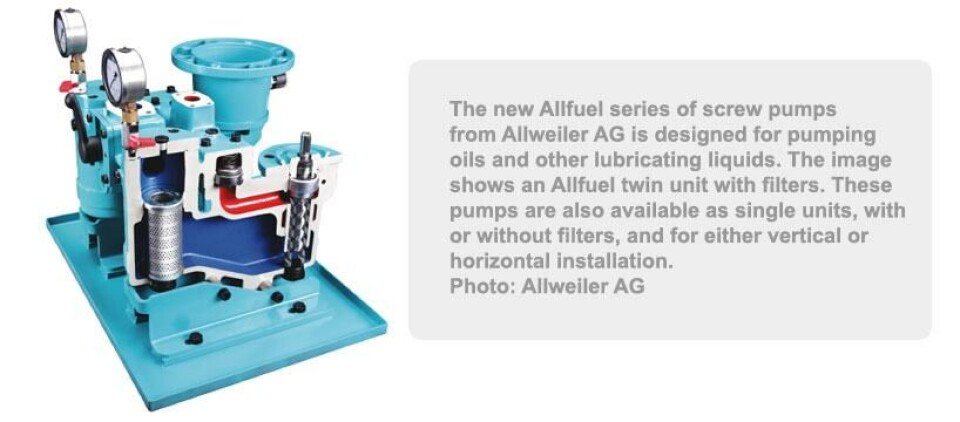

Allweiler introduces new “Allfuel” series of pumps for lubricating liquids

Allweiler AG, a business unit of Colfax Corporation, has been delivering its new “Allfuel“ series of screw pumps to customers since May.

Denne artikkelen er tre år eller eldre.

The new series is designed to move oils and other lubricating liquids with a maximum discharge pressure of 40 bar. Allfuel pumps are available in six different construction types, allowing them to adapt to a variety of pumping tasks and installations. Special Allfuel material combinations comply with the most recent regulations requiring ships in inland waterways and ports to be powered only by fuels that contain less than 0.1% sulfur.

“The new Allfuel pumps are very innovative. They lower operating costs by simplifying maintenance and increasing operational stability. At the same time, they meet current environmental standards and save space,” according to Allweiler CEO and Colfax Senior Vice President Dr. Michael Matros.

These new screw pumps were developed in collaboration with leading burner manufacturers to specifically target requirements in the market. In addition to many innovative details like heating elements for the mechanical-seal and filter chamber (which provides for smooth starting of the pump), these pumps also feature an innovative filter design that simplifies maintenance. By modifying how liquid flows through the pump filter, dirt particles are retained in the filter and held in place by a magnetic filter base. The design of the pump casing allows the filter to be changed without having to drain, dispose, and refill the oil. A vacuum meter continuously monitors the cleanliness of the filter, ensuring a continuous and adequate flow.

A new twin unit is available for situations where no interruptions are acceptable. A manual ball valve or an electronic switching unit facilitates rapid switching to the twin unit’s reserve pump. A non-return valve keeps the pump pressure-free while it is shut down, enabling straightforward removal and maintenance. The new twin units ensure that pumping continues without interruption.

Complying with stringent safety and environmental regulations demands highly innovative solutions. For example, in the past mechanical seals exhibited a standard leak rate that ensured proper operation, but that is no longer acceptable. To resolve this situation, Allfuel pumps can be equipped with the new “Allseal” leak detection and leak collection system. Allseal utilizes an opto-electronic sensor to monitor the condition of the mechanical seal, indicate when maintenance is needed, and prevent catastrophic and expensive pump failures when used in conjunction with an emergency-off controller. As an alternative to Allseal, a hermetically-sealed magnetic coupling can completely eliminate leaks for a very high level of safety.

Allweiler is the only pump manufacturer to offer a comprehensive approach to sealing, with products ranging from mechanical seals to leak-detection systems to hermetically-sealed magnetic couplings.