Farstad improves vessel operation with advanced condition monitoring

Farstad Shipping uses advanced condition monitoring to increase the efficiency and economic returns from its fleet of offshore support vessels. It is working closely with Rolls-Royce in using and contributing to further development of the Rolls-Royce HEMOS system.

Denne artikkelen er tre år eller eldre.

Far Searcher was equipped with a prototype HEMOS system several years ago. The 94m platform supply vessel (PSV), built in 2008 by Aker Yards Brevik to the Rolls-Royce UT 751 E design, has produced valuable data showing how vessel operation can be improved. The result is lower fuel costs, improved predictability and insight as to how maintenance can be better planned and less costly.

More effective operations through better information

-“Health, safety, environment and quality is an essential part of Farstad Shipping’s operations. The HEMOS system helps us to deliver even higher standards on all objectives. It greatly improves our ability to monitor and plan the need for maintenance, which is cost effective in itself as well as allowing us to deliver a more available and reliable fleet to the charterer. In addition the system monitors fuel consumption, which enables us to reduce emissions and cost of fuel in our operations,” says Børge Nakken, Vice President – Technology & Development in Farstad Shipping ASA.

Far Scorpion is an anchorhandler type UT 731 CD, built in Norway in 2009, 87.4m long and with a bollard pull of about 250 tonnes. The ship is equipped with a commercial version of the HEMOS system which has the ability to record and analyse data on board as well as transmit it to shore for additional analysis. Altogether about 4,500 points on the vessel’s systems can be monitored and recorded continuously. Not all of these are immediately important, and data analysis will normally be confined to key parameters indicating performance, for example fuel consumption related to operating mode and prevailing weather conditions, and wellbeing of items of machinery such as engines and thrusters in terms of temperatures, pressures and vibration levels. If anomalies are detected, the additional data records allow closer examination of potential problems. The best solution to the problem can then be found.

Long term opportunities and informed decision-making on board and ashore

If trends in the condition of equipment can be monitored and correctly interpreted, it can mean the difference between overhauling before failure occurs, instead of after a breakdown – just in time instead of just too late – with consequent saving in direct cost and consequential damage. Service intervals can often be extended. Other benefits from this will be improved predictability; where planned repairs can substitute unexpected breakdowns, offhire and insurance claims.

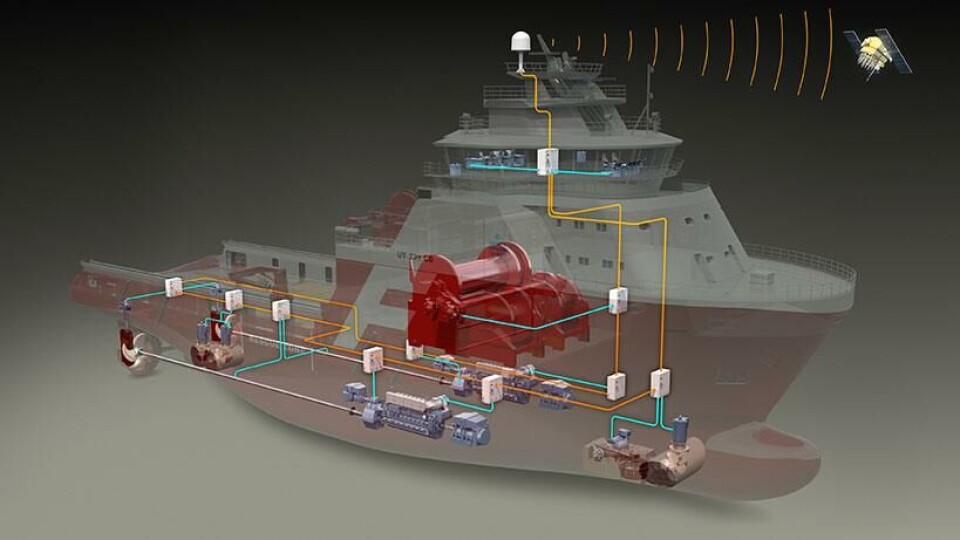

The Rolls-Royce HEMOS system is the enabler in this process. Sensors fitted on the Helicon-X3 propeller & thruster control systems, Towcon winch control system and Icon DP are connected to standardised HEMOS data acquisition cabinets that are hooked up to the Rolls-Royce integrated network. Data are administrated and stored at the on-board log-server together with ship operation and navigation data that are available on the same network and also data from the ship alarm and automation system. Analyses are performed and reports with real time information are presented on the HEMOS display on board. Data from the log server are transmitted on shore for extended analysis and reports. Acon@web is a new service using data from the HEMOS system to provide a number of reports with on-line and real time information from the ship operation and performance including fuel consumption and emissions. With Acon@web the ship owner may monitor a specific vessel, sister vessels or the entire fleet from a PC, lap-top or iPad.

“On Far Scorpion information is also analysed on board, and so is available to the vessel’s crew for informed decision-making, in addition to the information from the web ashore, which is available to all parties with access,” says Nakken.

The system offers considerable long term opportunities, in combining machinery data such as power developed and continuous recording of fuel consumption with navigation and weather data to improve the vessel’s overall operating efficiency and thus reduce consumption and emissions.

Offers considerable competitive advantages

Advanced condition and operation monitoring provides benefits to the vessel charterer, typically an oil major, and to the shipowner. To achieve success in winning a charter Farstad aims to present a better and more attractive vessel than competitors. Better in this context can mean a more efficient carrier overall, a PSV with a higher level of availability and reliability, a lower fuel consumption, or both. At one time the fuel burn of PSVs was not a major consideration. Now it is, not only because of the higher cost of fuel, but also the resulting emissions. Like Farstad, oil companies have become very aware of their own image where emissions are concerned, so a low emission and efficient vessel is more attractive. But in the short term the value of a superior vessel is not necessarily reflected in the dayrate, which is influenced by other market factors. However, the focus on fuel consumption and emissions as criteria for comparing different vessel candidates is increasing among the charterers.

Farstad is looking for its own economic gain from installing advanced condition monitoring, apart from making a vessel more attractive to the charterer. With HEMOS the immediate gain is avoiding machinery breakdown through timely intervention based on hard information. Slightly longer term is the ability to plan maintenance better and more cost-effectively by extended time between scheduled overhauls. Working with the classification society it will also be possible to avoid opening up for survey machinery that is running without problem in a controlled environment. Unnecessary dismantling and reassembly may often shorten the lives of bearings and seals.

Enables offshore crew to diagnose potential problems

“We see several direct benefits from HEMOS and continuous health monitoring. One is timely warning of the need for maintenance. Another is in planning work to be done during drydockings or port visits,” says Børge Nakken. “Rolls-Royce can improve its service offer by knowing well in advance what spares or exchange units are likely to be needed, so that they can be available at the right location at the right time. The process also helps with maintaining an optimal level of spare parts, reducing the cost of parts storage, and rationalising production of spares, with economic advantages to all parties.”

A valuable feature of HEMOS is that all data is available both to the people on board and to the office ashore. Farstad has experienced and highly competent crews, who are quite capable of diagnosing potential equipment and system problems, and it is very important to Farstad to avoid the ‘big brother is watching you’ attitude by sharing the same information between all involved parties. Instead, most matters can be settled either on board or by informed discussion. Since operating the vessel at maximum efficiency is vital, and most of the vessels operate with two crews who alternate, a little competition is healthy, and data from HEMOS gives each crew the information they need to compare with others and get the best out of the ship.

Improves health and safety work through better incident reporting

Farstad Integrated Management System also operates an incident reporting system, and the HEMOS data and records are a tool for gaining an accurate oversight of the conditions if an incident happens and an aid in planning procedures that reduce the probability of future incidents.

Ship motion information in real time is also captured by HEMOS from the vessel’s MRU (motion recording unit). This information is available for a health monitoring study - in this case the health and wellbeing of the crew, not the machinery – which Farstad is carrying out with SINTEF Helse. The research programme, among other things, looks at the impact of vessel motions on crew performance, and the effect of different watchkeeping patterns on fatigue.

In the longer term, recording and analysis of operating data gives Farstad an improved basis on which to specify the next generation of offshore vessels, selecting the best hullform, power and propulsion system to meet anticipated needs of charterers.

There is also a gain for Rolls-Royce in ship and equipment system design. Full details of the loads imposed on thrusters, engines and other equipment enable design improvements to be made. They may also suggest new technology or products by substituting operating facts for assumptions, and by revealing the actual full scale stresses on an actual vessel doing a specific task in a specific seaway.