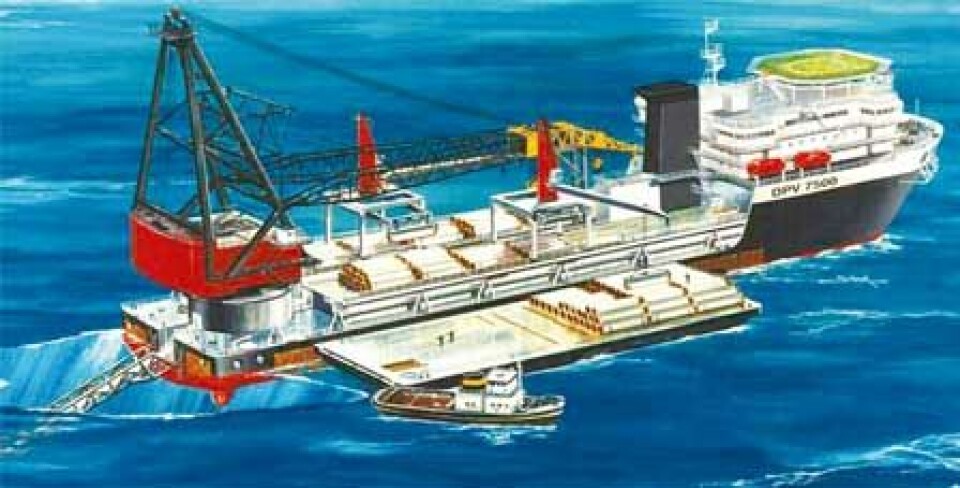

Chinese subsea pipelaying vessel with Wärtsilä power

Wärtsilä is to deliver a power plant and thrusters for the largest pipelaying and crane vessel ever built in China. In addition to the pipelaying vessel, equipment for use in the extensive Deepwater Project includes a semi- submersible drilling rig, two anchor handling tug supply vessels and seismic and research ships. For Wärtsilä the contract will be an excellent reference with high public relations value.

Denne artikkelen er tre år eller eldre.

The contract between Wärtsilä and CNOOC Engineering Ltd, a subsidiary of the China National Offshore Oil Corporation (CNOOC), was signed in March 2007. Founded in 1982, CNOOC is a state- owned industrial giant which explores for oil and gas and produces petrochemical products and fertilizers. In 2006, sales by CNOOC totalled RMB 132.4 billion with a net profit of RMB 49 billion. From its base in China, CNOOC has now expanded its operations into more than ten countries.

Innovative and efficient, CNOOC has been selected by Standard and Poor’s as a “Global Challenger” in three successive years. – CNOOC has made notable progress in deepwater exploration and believes that activity in deepwater areas will expand the company’s future growth opportunities. The Deepwater Project is a part of that growth scheme,”says Li Xiao-Liang, Sales Manager from Wärtsilä in Shanghai.

A pioneer in China

The double-deck pipelaying and crane vessel DPV7500 will be built in China by Rong Sheng Heavy Industries Co., Ltd. The vessel has an overall length of 204.65 metres, a beam of 39.2 metres and a depth of 14 metres, and has a transit draught of seven metres. The largest pipelaying vessel ever to be built in China, it will lay subsea pipelines in water up to 2000 metres deep at a speed of five kilometres a day using a central firing line and a fixed stinger.

The firing line will be located on the main deck and covered by a top deck on which pipes are stored. Adjacent to the firing line are two double joint-preparation lines. The storage facilities can accommodate up to 9000 tons of pipe. Two travelling gantry deck cranes, rollers and conveyors will be used in pipe handling and transfer.

– At the stern, the vessel will be equipped with a revolving crane able to lift 4000 tons when fixed and 3500 tons when revolving, says Göran Österdahl, Sales Director, Merchant, Wärtsilä Ship Power in Shanghai.

The vessel will be equipped with dynamic positioning technology. In practical terms, this means that satellite signals and steerable and retractable thrusters will be utilized to maintain the vessel’s position under all conditions.

The ship will have accommodation for 380 people. After her launch in late 2009 or early 2010, although her main area of operation will be the East China Sea, South China Sea and South-East Asian waters, she will be able to offer its services world-wide.

The Wärtsilä contribution

Wärtsilä will be supplying six 12-cylinder Wärtsilä 32 diesel generating sets with a combined power output of 34.6 MW, two 4500 kW steerable thrusters and five 3200 kW retractable thrusters. The generating sets are well suited to the varying power demands of the electrically-driven dynamic-positioning thrusters. They comprise an entire onboard power plant. Wärtsilä’s deliveries will take place in mid 2009.

– The demand for redundancy in this kind of installation is high, because the vessel must be able to maintain her position in extreme conditions even if one of the thrusters or engines breaks down. Environmental regulations in the oil industry are strict. No oil leaks are allowed. It would be bad PR for a large oil company, says Österdahl.

As a major supplier to the oil industry, Wärtsilä has long experience in well-proven and environmentally sound technologies for the marine and offshore markets. Similar solutions to those employed in the new pipelaying and crane vessel have been delivered and successfully used on a large number of drill rigs.

Business with a reliable supplier

CNOOC and Wärtsilä had an established business relationship before negotiations concerning power plant for the pipelaying and crane vessel began. Earlier Wärtsilä projects with CNOOC included delivery of three 16-cylinder Wärtsilä 32 generating sets in V-configuration with power management and fuel oil treatment for the NB35-2 crude oils platform and three 16-cylinder Wärtsilä 32 generating sets in V-configuration with fuel oil treatment for the Nanhai FPSO (Xijiang 23) project.

For the pipelaying and crane vessel project, CNOOC was looking for a reliable supplier who could provide a complete power and thruster solution. – It was in the customer’s interest to simplify their project management by avoiding the need to interface with a large number of suppliers, says Österdahl. – We were pleased to offer CNOOC a total solution as well as low rates of fuel consumption and other technical benefits - and we won the contract.

In addition to equipment for the pipelaying and crane vessel Wärtsilä will be supplying the Deepwater Project with eight 12-cylinder Wärtsilä 32 generating sets in V-configuration with all auxiliaries, and eight 4600 kW underwater-mounting type thrusters for a semi- submersible drilling rig. – We are proud that China’s biggest offshore operator has chosen us as their partner. As a global player this is a very valuable reference for us. We’re convinced it will further strengthen our position as a supplier to the marine and offshore industries in both Asia and other parts of the world,” says Österdahl.

Specification of CNOOC’s new Subsea Pipelaying and Crane Vessel:

Design by Gusto (Holland) DPV 7500

Built by: Rong Sheng Heavy Industries Co., Ltd.

Length (O.A): 204.65 m

Length between P.P: 185.00 m (at transit draught)

Breadth (MLD): 39.20 m

Depth (MLD): 14.00 m

Draught (transit): 7.00 m

6 x Wärtsilä 12V32 main power generating sets

2 x 4500 kW Wärtsilä Steerable Thrusters type LIPS FS3500/MN

5 x 3200 kW Wärtsilä Retractable Thrusters type LIPS FS2510/2500MNR

The vessel is double classed, ABS and CCS with a Class III dynamic positioning system (DP3)

Subsea pipelines in water of depth up to 2000 m

Pipelaying speed 5 km/day

Pipe storage up to 9000 tonnes