Autoload for Edison Chouest Offshore

Autoship Systems Corporation has announced that Edison Chouset Offshore LLC (ECO) of Galliano, LA, USA has chosen to have their offshore fleet of vessels outfitted with the Autoload: onboard stability program.

Denne artikkelen er tre år eller eldre.

– The delivery of the Autoload software will be a staged roll-out for the ECO fleet. The initial install is set for 68 of the latest-delivered and soon-to-be delivered vessels. Staging after this group will be the remainder of the ECO deepwater fleet, inclusive of PSVs, AHTSVs and Deep Water Support Vessels. When the effort is completed, over 150 ECO vessels will be fitted with the Autoload software. This significant installation of the Autoload program will help ensure that the ECO fleet is operating under the strictest of stability criteria, states Gary Rook, Technical Director for ECO.

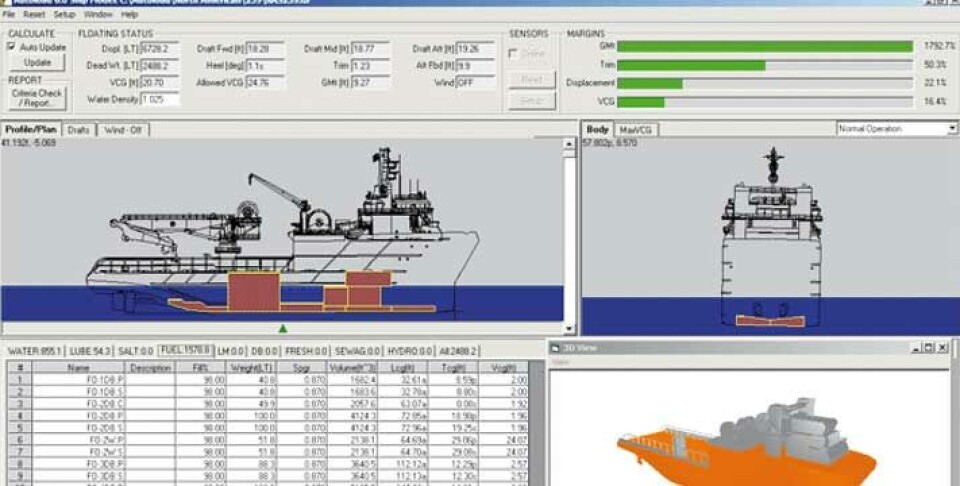

Autoload is an advanced loading program that offers “real-time stability” for every vessel type. With over 550 installations world-wide, Autoload has become the program of choice among the offshore sector including: Bourbon Offshore, Swire Offshore, Solstad Offshore and all vessels built by Rolls-Royce.

All ECO AHTS vessels will be delivered with specific anchor handling functions plus several will be fitted with a unique Crane Module to suit a heavy lift offshore crane. All their installations will be fitted with a Tank Sensor program that interfaces directly with Autoload thus providing immediate tank loadings for an accurate and up-to-the-minute analysis of the vessel’s stability.

ECO owns and operates a growing fleet of new generation offshore service vessels supporting a vast majority of the U.S. Gulf deepwater market, as well as a large independently owned fleet of research vessels. ECO’s high-tech, high-capacity offshore vessels range from 87 feet to 348 feet, and are beyond comparison to any competition.

The builder of the Edision Chouset Offshore fleet is its sister company, North American Shipbuilders (NAS). The shipyard has a long relationship with Autoship Systems dating back to 1992 when ASC supplied the industry’s first PC hull design, plate expansion and hydrostatic programs to NAS’ Engineering Department. Many of the vessels in the ECO’s fleet have been modeled in Autohydro (hydrostatic & stability program) allowing for a fast completion schedule of the Autoload installations.

Autoship Systems Corporation

Autoship Systems Corporation is a marine software developer of innovative onboard stability and load planning software and an integrated CAD/CAM design program suite.

ASC Offshore systems integrate draft, stability, ballast, structural strength, cargo, and other data in real time, and provide the tools necessary to make the best possible use of this data for both operations and planning. The software is individually set up to reflect each rig, platform, or support vessel; however, users with multiple installations benefit from both a common interface and a flexible database structure - linking operations and planning functions at sea and ashore.

The capabilities available in ASC Offshore solutions are usually organized into two general product types: Autoload Offshore stability software and ASC Deck Loading/Cargo Management software.

Autoload Stability Software Systems is developed from a proven line of stability software products that have been operating in a diverse range of vessel types for more than 10 years – including Offshore Support, Tanker, Heavy Lift, Bulk, Container, RoRo, Naval, Coast Guard, Survey, Cable, and Cruise Ships. Autoload makes calculations based on exact digital models – which means you always get simulation based on real parameters and not on interpolation of table-based values. Autoload can input data from any sensor system one chooses to operate, and can also accept manually entered data at any time.

ASC’s Deck Loading/Cargo Management software gives the customer a highly organized, accurate, flexible, and straightforward system of creating, editing, and tracking loading/stowage plans. These systems can be used to plan, model, and track stowage of all types of cargo – point weights, distributed weights, bulk oil stowage, containers, etc. Real-time planning and operations are integrated in a common interface, improving safety and efficiency at every stage.

The features that make such stowage plans possible include:

• Sophisticated graphics with both global and highly detailed displays of all stowage areas.

• Synchronization – at any stage in the process – between planned and actual loading/stowage data.

• Cargo grouping in the interface according to customer needs (for example, shipper, cargo type, hazardous material classifications, deck limitations, etc).

• Automatic Stowage Checks for IMDG Segregation, deck height, weight, pressure, and area limitations, cargo space conflicts at every upcoming port, unstackable cargo, etc.

• A highly sophisticated interface that deals with large quantities of cargo quickly and easily, but permits fine adjustments to individual cargo items.

• Organized information display based on departure and arrival conditions for each item to be loaded.

• Highly accessible stowage data – when and where you need it – without ever leaving the deck display.

• Graphic and tabular reports at any stage, tailored to port, cargo type, HAZMAT, and user requirements.

• Overall cargo space utilization by deck, cargo type, and by percent of total available.

• Tailorable stowage rules for use in automatic stowage operations.

• Flexible standardized stowage patterns for consistent and predictable conditions (cargo, vessel , port – preventing unnecessary repetition of effort.

Autoship Systems Corporation / Coastdesign Norway will be present at Nor-Shipping 2009 at Booth A1-58.