Knowledge sharing on condition monitoring at SMM

Rovsing Dynamics gathered ship owners, classification societies and machinery makers at SMM to exchange views and experience with vessel condition monitoring.

Denne artikkelen er tre år eller eldre.

Condition monitoring of mission critical vessel machinery is rapidly becoming industry standard. Rovsing Dynamics, a MAN Diesel approved condition monitoring supplier, provided a forum for knowledge sharing at the SMM trade fair in Hamburg. The open seminars were titled “Vessel Condition Monitoring for Condition Based Maintenance – What to gain and how to get there.”

Ship owners, who have implemented monitoring solutions together with Rovsing Dynamics, will share their goals and practical experience with monitoring of main engine bearing wear, thrusters and turbochargers. These include PRISCO (tankers), Reederei F. Laiesz (Car carriers) and Scandlines (ferries). DNV, Germanischer Lloyd and Lloyd’s Register will present their guidelines for a successful Condition Based Maintenance strategy, supplemented by the requirements of MAN Diesel, who now recommend ship owners to completely omit regular open-up inspections of the crank-train bearings of certain engine types with an approved bearing wear monitoring system, among other things.

Ship owners monitor critical machinery for various reasons. Most want to avoid damage and save millions on repair costs and off-hire. As one example a ship owner, who monitors main engine and turbochargers, discovered a turbocharger problem in due time to take action, thereby avoiding risk of significant consequential damage. Some also aim to increase vessel availability by omitting costly, time-consuming open-up inspections and only conduct condition based maintenance. Early adopters have moved from test to implementing online monitoring on their new ships as well.

– According to our customers, guidelines and support from classification societies and machinery makers are paramount for a successful implementation of condition monitoring, said Rovsing Dynamics’ CEO Thea Larsen. – But it seems that each classification society create their own guidelines. Recently, one of these suggested that class and machinery suppliers should work together to harmonize specifications for exchange of condition monitoring information to facilitate wider implementation of Condition Based Maintenance. We therefore took the initiative to host a forum at SMM for dialogue between all parties involved.

Last year the company hosted a similar successful event in Athens, where ship owners encouraged the class and engine designers to make condition monitoring mandatory. Today, this seems to be much closer to reality.

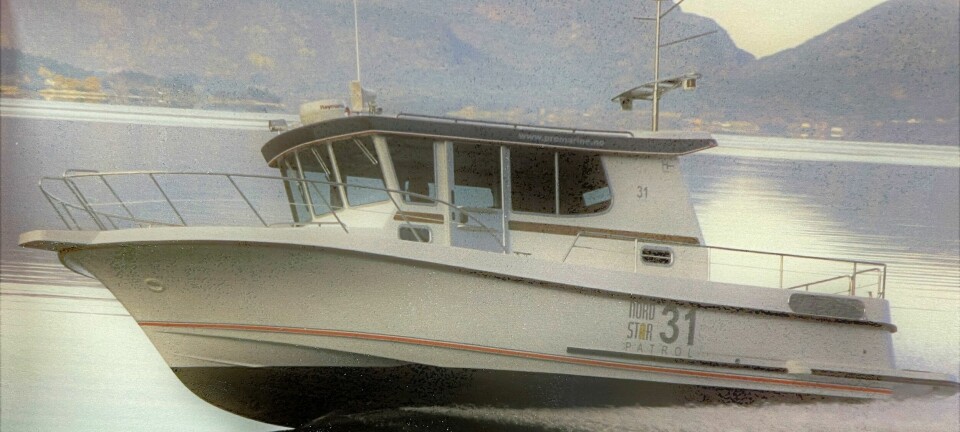

Contract with Trico Marine Services

Trico Marine Services Inc., a leading US provider of marine support vessels to the offshore oil and gas industry, is to install advanced online condition monitoring solutions from Rovsing Dynamics on its 8 new multi-purpose vessels (MPVs). The new 2,900 dwt supply vessels will be dedicated to subsea installations for e.g. floating production, storage and offloading vessels (FPSOs).

The versatile OPENpredictor solution will monitor the condition of 4 tunnel thrusters as well as the main reduction gear on all 8 vessels. This can be performed with only one online system per vessel.

Another OPENpredictor solution for Azimuth thrusters has been operating on a Scandlines ferry for more than a year. Since Rovsing Dynamics began developing solutions for maritime use four years ago, numerous customers have installed stand-alone or combined solutions to monitor diesel engine bearing wear, turbochargers, pumps and thrusters on containerships, tankers, car carriers, multi-purpose vessels and ferries.